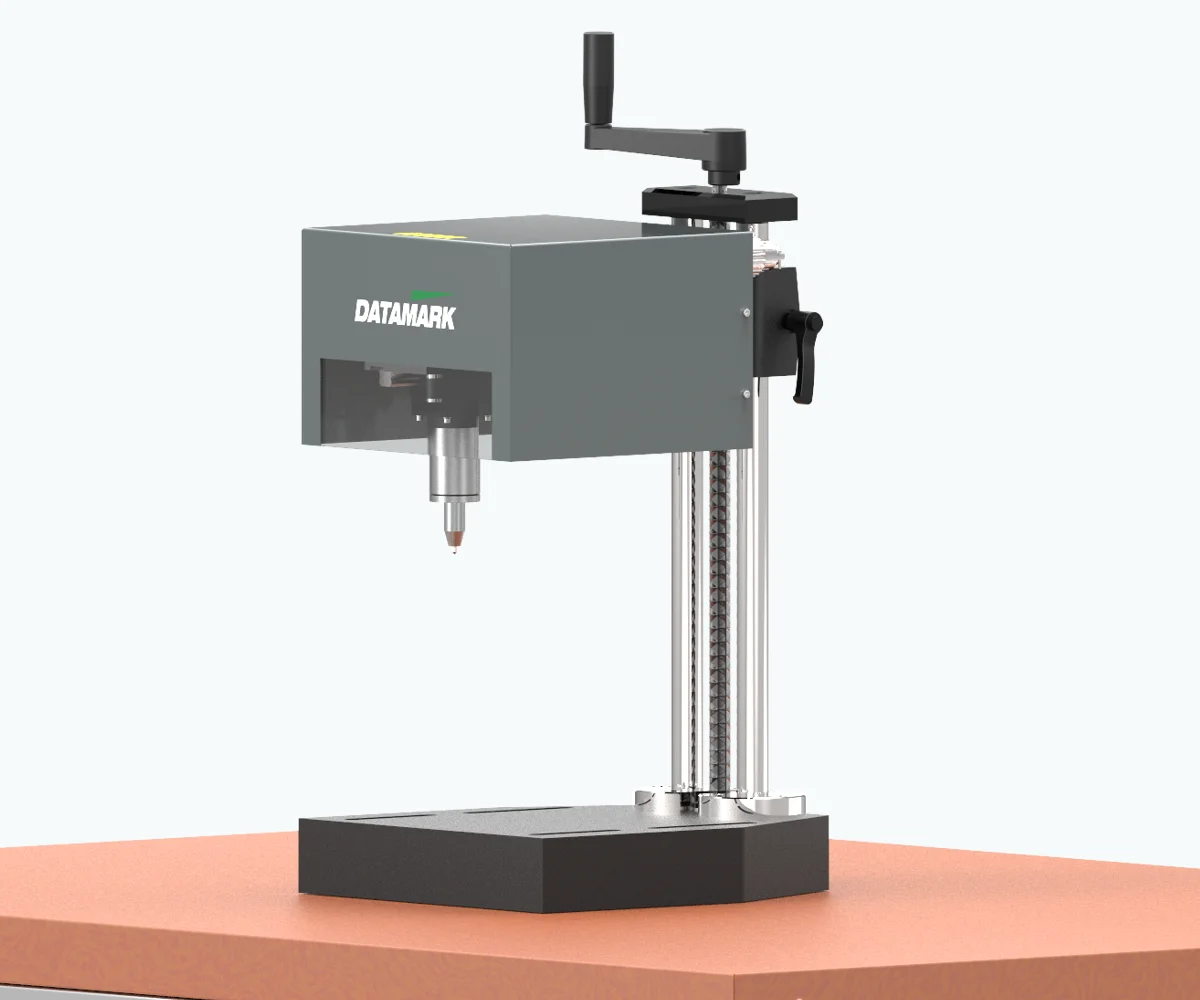

Datamark™ POWERMARKER Benchtop Dot Peen Marking Machine

Datamark™ POWERMARKER dot peen marking system offers the highest performance and features of all benchtop dot peen marking systems available in the industry.

This powerful marker is equipped with a programmable Z-axis and the Autosense system to automatically adjust the marking height, what is ideal for carrying out automated and precisse marking on high-value and complex parts in the aeronautics and automotive industries, among others.

Datamark™ POWERMARKER Benchtop Dot Peen Marking Machine

Benchtop Dot Pin Marking Machine for Automatic Engraving Parts and Tags

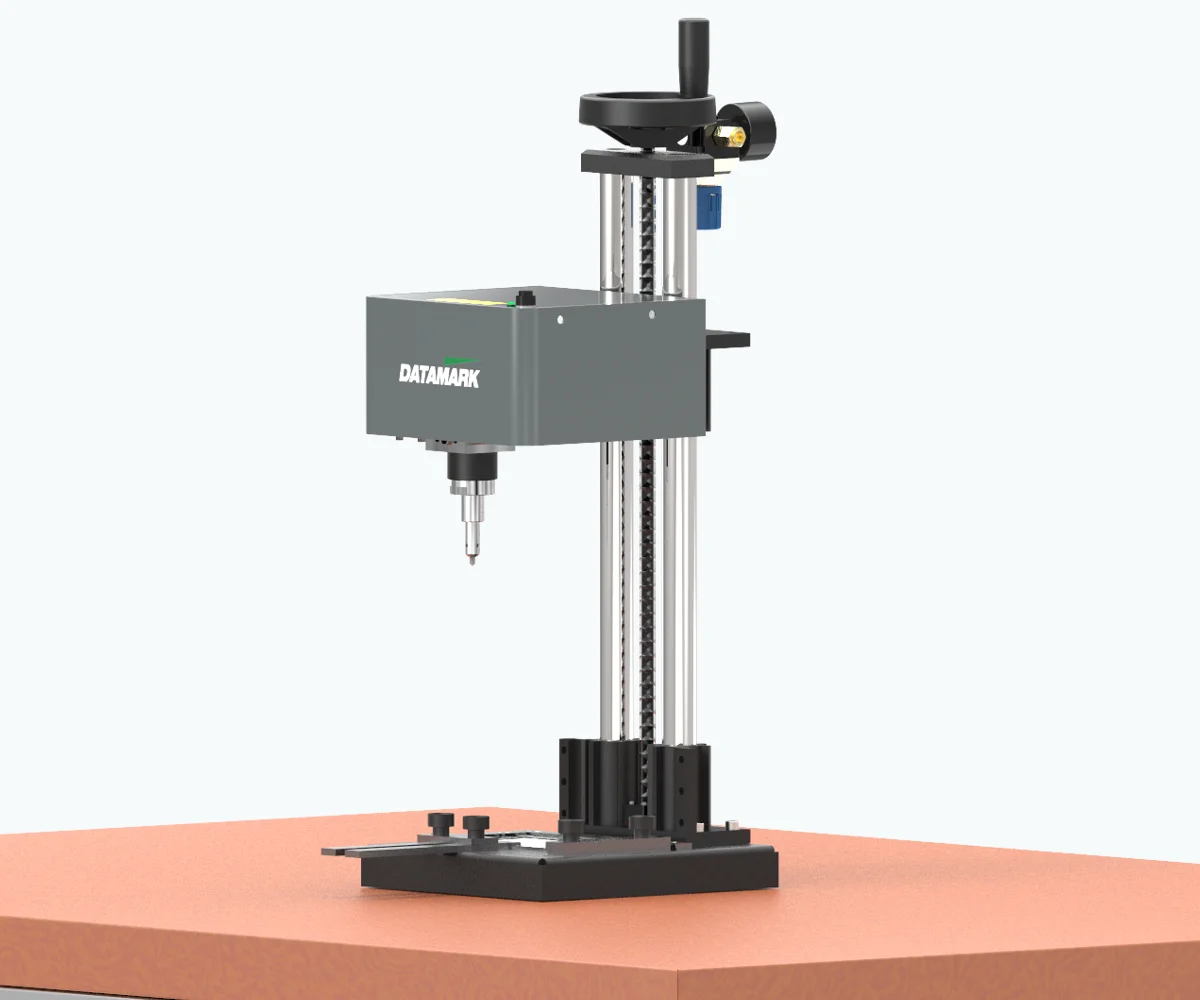

Electric Z-Axis

The programmable Z-Axis allows to automatically adjust the height position of the marking head on the part.

Autosense System

The marking machine is equipped with the Autosense system that automatically detects the height of the part and adjusts the marking distance with total precision.

Powerful marking

Datamark™ POWERMARKER marking machine’s electromagnetic marking head offers maximum marking precision with electronic control of marking force/depth.

Robust construction

Made entirely of metal, it is ideal for working in harsh environments where high reliability and intensive use are required.

Direct PC control

The marking messages can be easily programmed using the fully featured Datasoft PC software included with the marker.

Flexible communication

The connection between the PC and the marker is directly established through LAN / Ethernet network cable or via wireless WiFi connection.

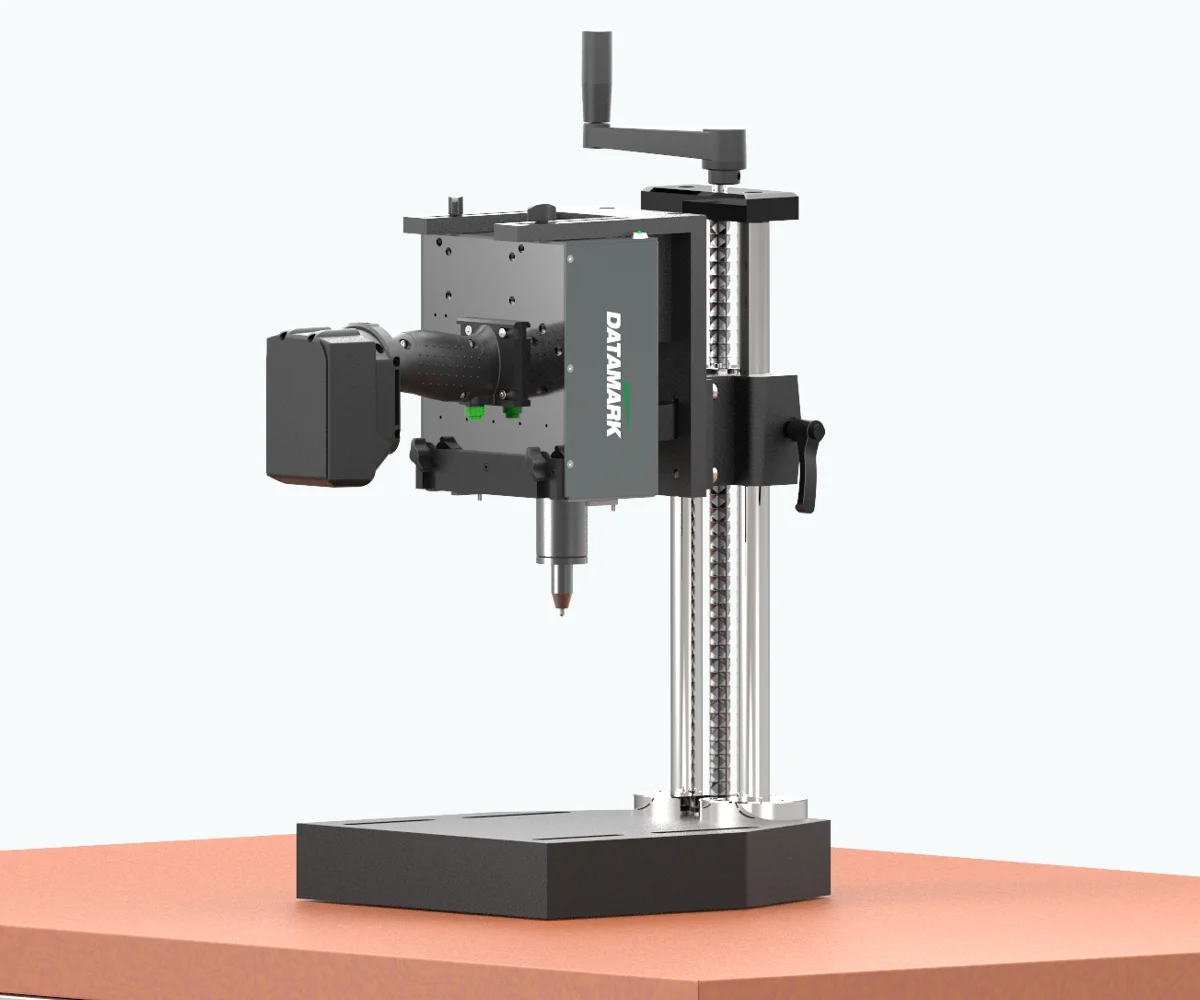

Rotary Axis

The optional rotary axis allows radial marking up to 360º around cylindrical parts up to 30 kg in weight.

Wide variety of marking applications

Datamark™ POWERMARKER is a perfect solution for nameplates and tags engraving, datamatrix barcode marking, serial marking, tool marking, logo marking, etc.

Key Features

- 1

Electric Z-Axis.

- 2

Autonsense System.

- 3

120 x 100 mm marking window.

- 4

Powerful PC control.

- 5

Ethernet connection.

- 6

Datamatrix marking.

- 7

Rotary Axis available.

Datamark™ Dot Peen Marking Machines