Datamark™ PRO+ Fiber Laser Marking System

Datamark™ PRO+ fiber laser marking machine is ideal for making permanent, top-quality marks on a wide variety of materials, parts and products; laser marking on metalls, alloys and most plastics.

The PRO+ laser marking system incorporates the most advanced MOPA laser technology for higher performance in the most demanding and high-speed laser marking and engraving applications.

Datamark™ PRO+ Fiber Laser Marking System

The Premium Industrial Laser Marking System with Advanced Integration Capabilities

Reliable compact design

Datamark™ PRO+ is a high-performance fiber laser marking system with advanced features, designed to solve the most demanding industrial marking applications. In adittion, its robust, high-quality construction ensures reliable integration into production lines, assembly and manufacturing cells or automated workstations.

High laser marking performance

Equipped with a powerful 30, 50 or 100 watt advanced MOPA fiber laser engine, the Datamark™ PRO+ marking system allows you to easily create top quality markings on a wider variety of materials.

Maximum installation flexibility

Datamark™ PRO+ laser marking system is very easy to install in multiple configurations; as well as a desktop / open class 4 laser marking system or directly integrated in the production line.

Advanced integration

Datamark™ PRO+ laser marker features network connectivity via LAN/Ethernet interface for direct integration with the company’s MES-ERP production systems. Besides the IN/OUT interface is fully configurable and facilitates total control of the marking process through PLC systems.

Stand-Alone operation

Datamark™ PRO+ is equipped with an onboard high-speed processor and flash memory to carry out the marking process without having to be connected to a slave control PC.

Fly-Marking capability

The Datamark Fiber Laser Pro+ laser marking machine offers unparalleled fly marking capabilities, enabling high-speed, continuous marking on moving production lines. With precise control and advanced technology, it ensures seamless integration and superior marking quality, even at high production speeds.

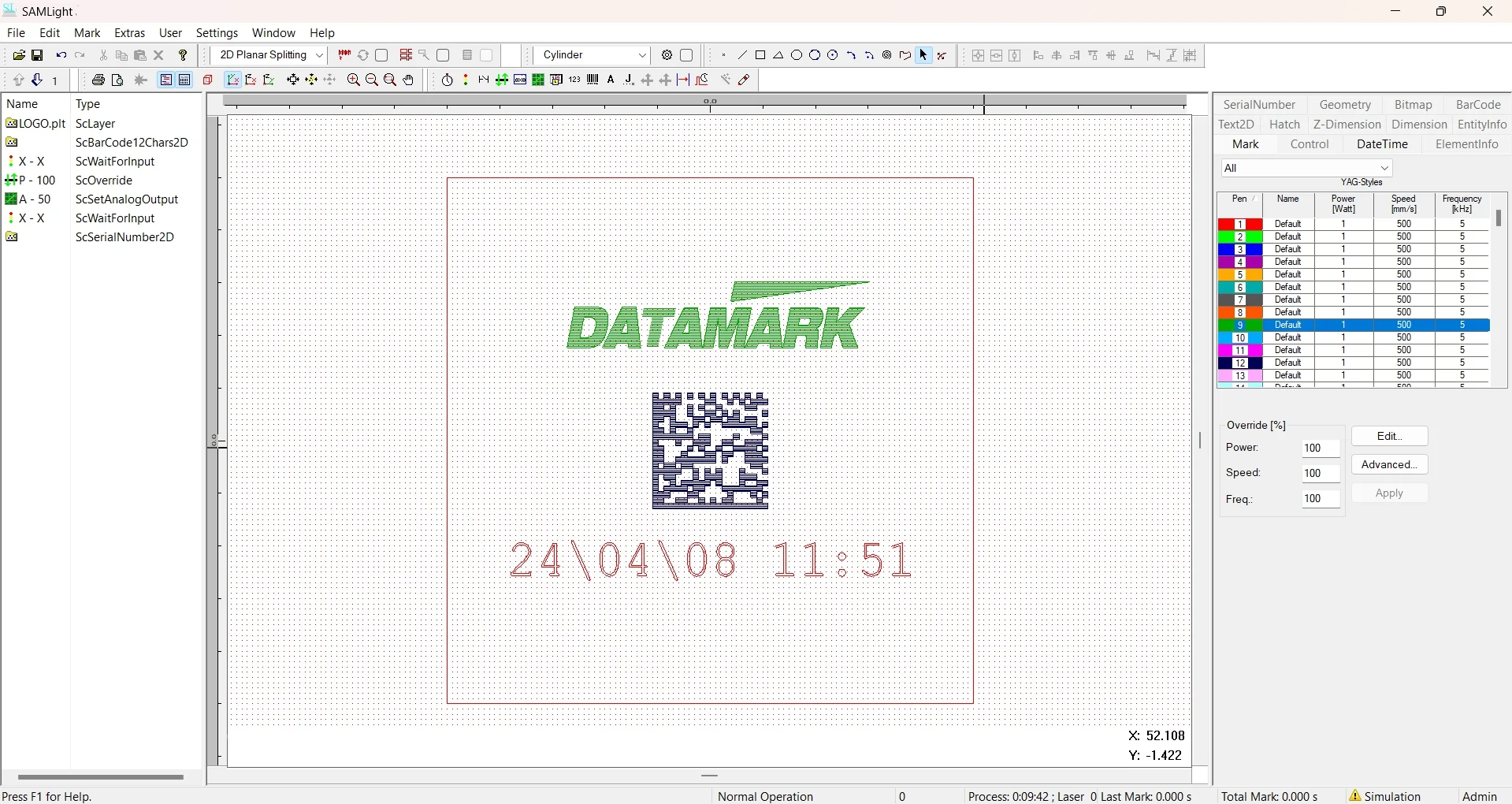

Easy marking programming

Marking programs are created with the fully featured laser marking PC software that includes all design functions to easily solve from standard to the most advanced fully automated marking applications.

Affordable cutting-edge tecnology

Datamark™ PRO+ allows companies to access the most advanced laser marking technology at highly competitive prices, for a totally safe and fast return on the initial investment.

Key Features

- 1

High quality industrial grade construction.

- 2

30W, 50W or 100W MOPA Fiber Laser.

- 3

Rack-type industrial controller.

- 4

Advanced connectivity for marking automation.

- 5

Embedded controller for stand-alone operation.

- 6

Built-In Focus Finder Tool.

- 7

IO for Automated System Control.

Datamark™ Laser Marking Systems