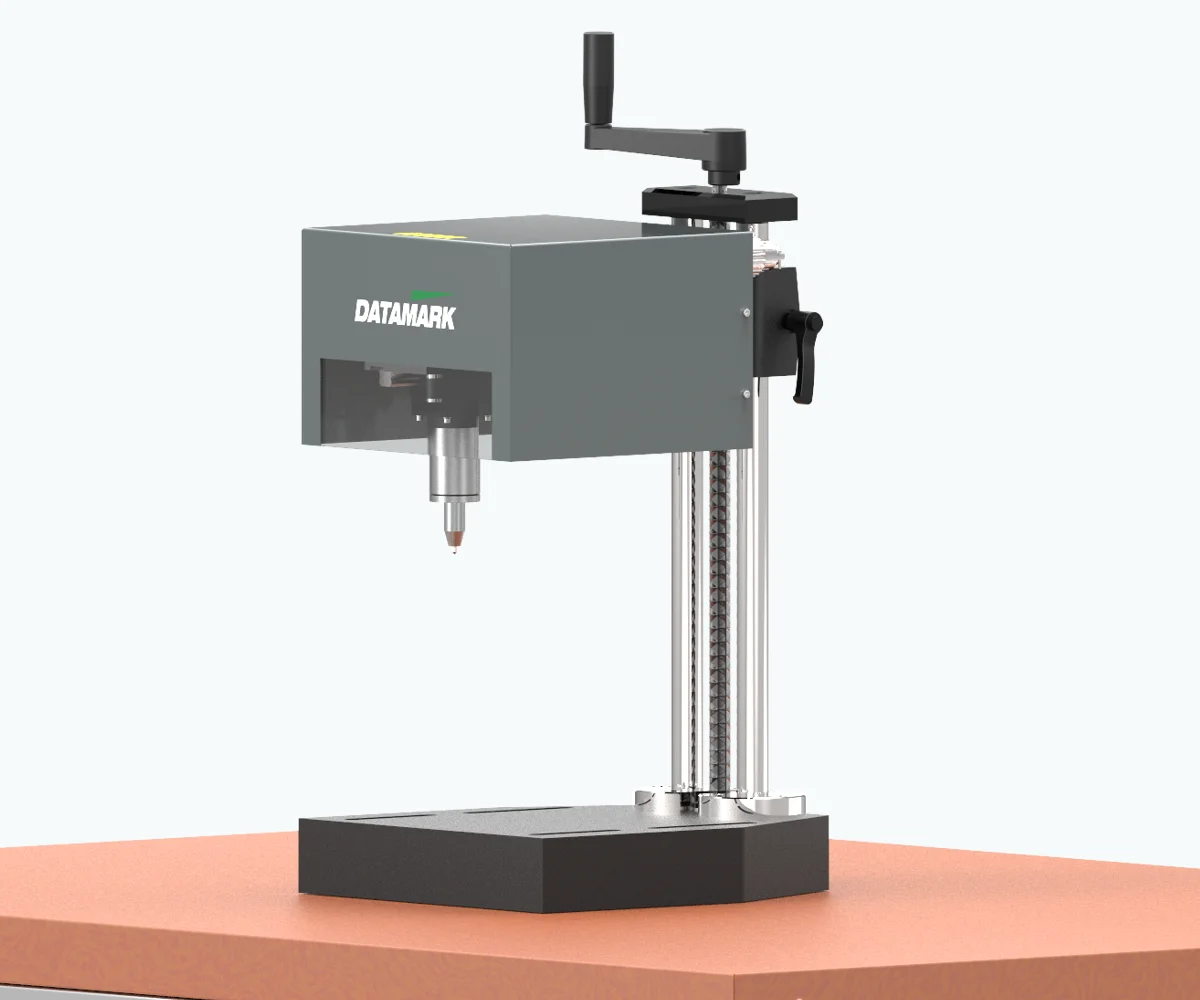

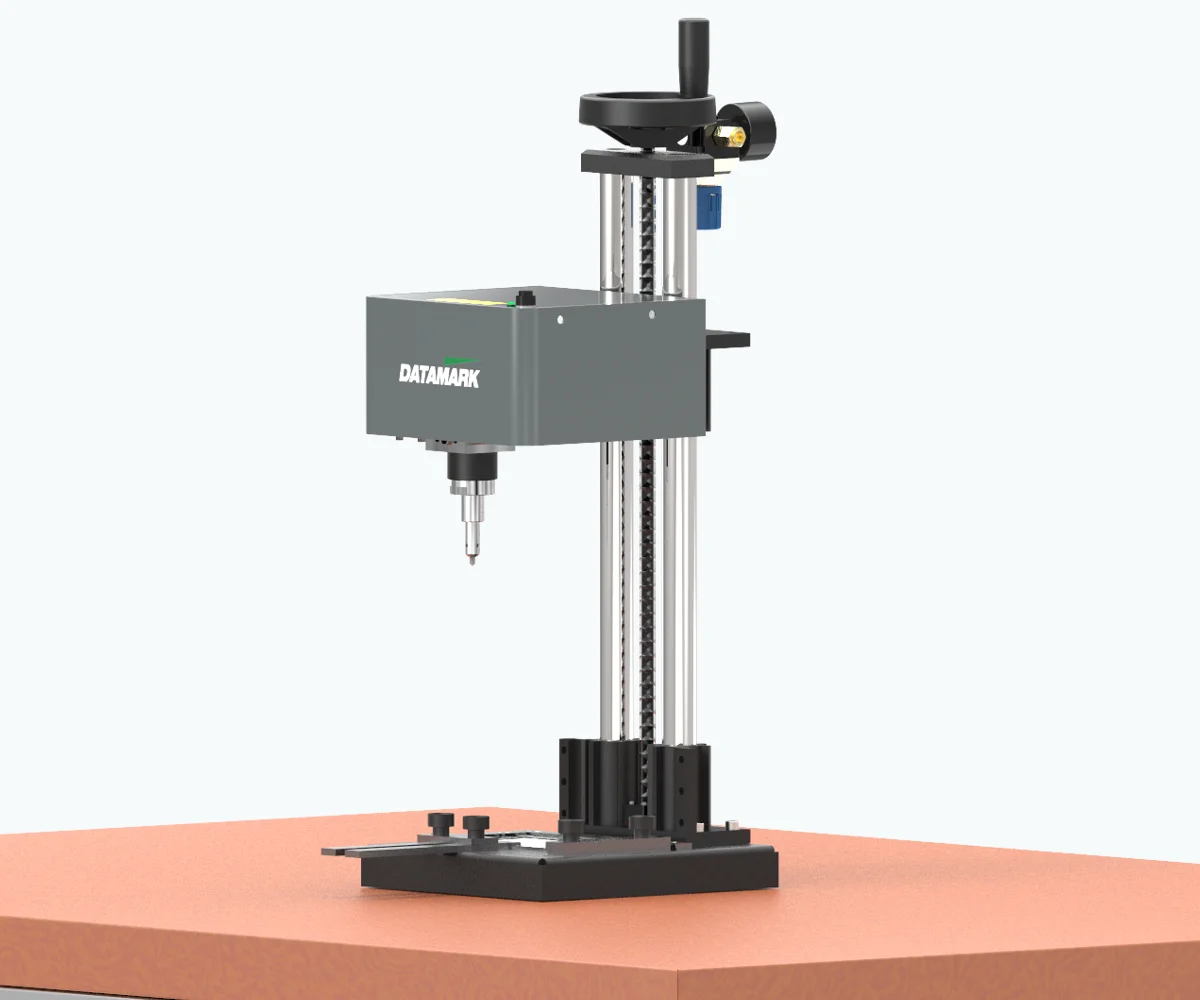

Precision Dot Peen Marking Machines for Metal Machined Parts

Explore DataMark’s cutting-edge dot peen marking machines for precise and durable marking on metal machined parts. Enhance traceability and compliance effortlessly.

Are you seeking a reliable solution for marking metal machined parts with precision and durability? Look no further than DATAMARK’s advanced dot peen marking machines. Our state-of-the-art technology ensures impeccable marking quality, enhancing traceability, identification, and compliance in various industrial settings.

Why Choose DATAMARK Dot Peen Marking Machines for Metal Machined Parts Marking?

Precision Marking

Achieve crisp, high-resolution marks with our advanced dot peen technology, ensuring clear identification of part numbers, serial numbers, logos, and more on metal machined parts.

Durable Results

Our dot peen marking machines create deep, indelible marks that withstand harsh environmental conditions, including abrasion, chemicals, and extreme temperatures, ensuring long-lasting legibility.

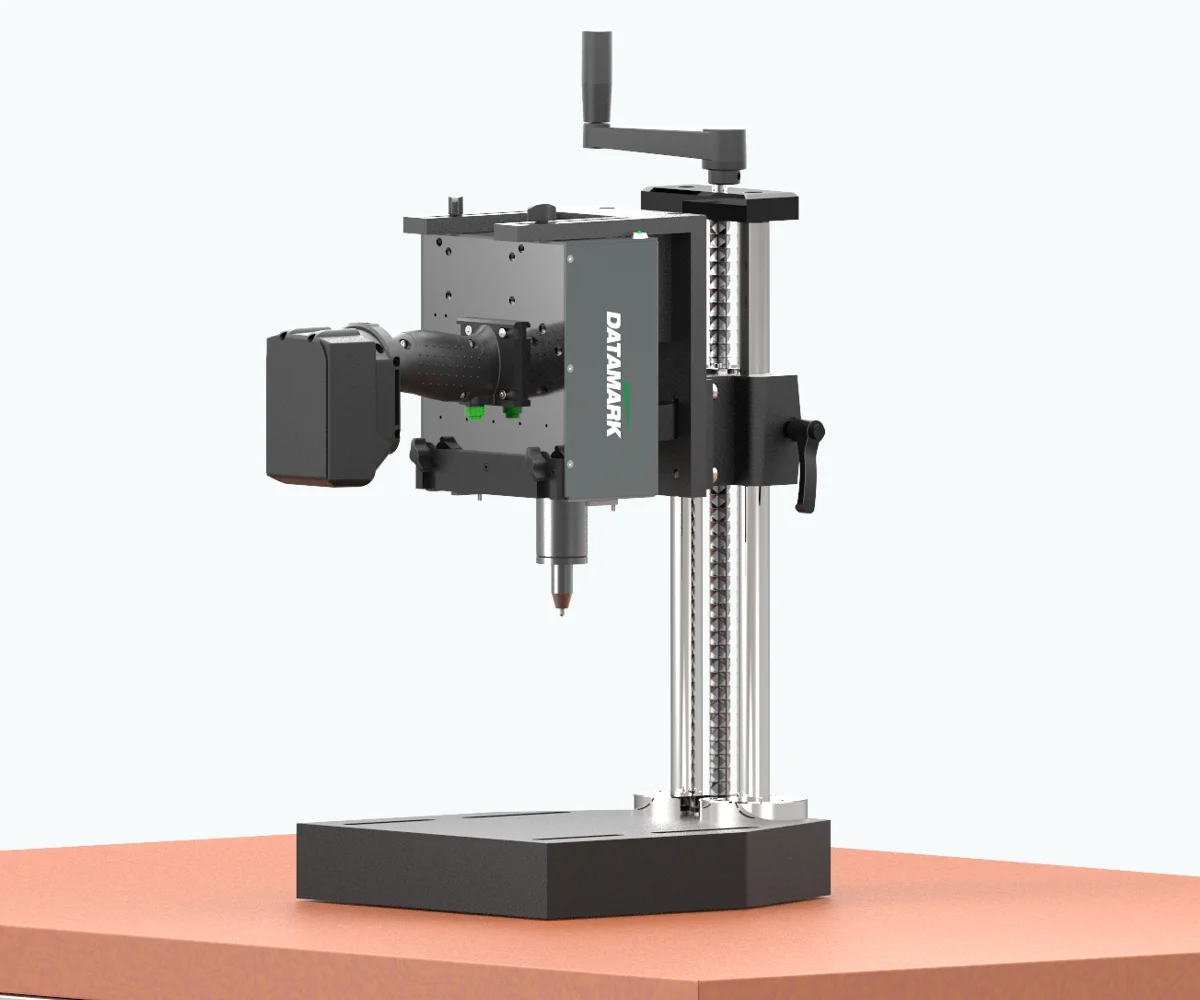

Versatile Application

Whether you’re marking stainless steel, aluminum, brass, or other metals commonly used in machining, DATAMARK’s dot peen marking machines deliver consistent, reliable results on a variety of surfaces.

Efficiency and Productivity

Streamline your marking processes with DATAMARK’s efficient dot peen technology. Our machines are designed for high-speed operation, allowing you to meet tight production deadlines without sacrificing quality.

User-Friendly Interface

Experience ease of use with our intuitive user interface and software, facilitating seamless operation and quick setup for even complex marking tasks.

Customization Options

Tailor your marking solutions to your specific requirements with our range of customization options, including stylus configurations, marking depths, and marking patterns.

Datamark™ Dot Peen Marking Systems

Our dot peen marking machines are ideally suited for a wide range of applications in the metal machining industry, including:

- Marking part numbers, serial numbers, and date codes on metal machined components.

- Adding logos, branding, and regulatory information to metal parts.

- Enhancing traceability and compliance in automotive, aerospace, medical, and electronics industries.

- Supporting quality control and inventory management processes.

- Preventing counterfeiting and ensuring product authenticity.