Benefits of Datamark Dot Peen Marking Systems

High marking precision

Our dot peen marking machines offer unmatched precision in marking parts, as they allow for fine control over the depth and width of the marks. This makes our dot peen markers an ideal solution for industries where precision is key, such as aerospace, automotive, oil-gas, construction and more.

Versatility

DATAMARK dot peen marking machines can mark a wide range of hard materials, including metals, alloys and plastics. This makes it a versatile solution that can be used in a variety of industries and applications.

Durability

Dot peen markings are highly durable and resistant to wear and tear, making them ideal for applications where the product will be exposed to harsh environments, such as in the automotive industry.

Marking speed

DATAMARK dot peen marking machines can mark parts and products at high speeds, making them an efficient solution for high-volume production lines.

Low-stress marking

Dot peen marking technology is a low stress process, which means that it does not cause any damage or change the physical properties of the material. This is especially important in industries where the product being marked must maintain its specific properties.

Customizability

Our dot peen marking machines offer a wide range of customizable settings, allowing for the creation of unique and intricate marks. This is especially important for branding and identification purposes.

Environmentally-Friendly

DATAMARK dot peen marking machines are an environmentally-friendly solution, as they do not require the use of inks, solvents, or other chemicals that can harm the environment.

Unbeatable value for money

DATAMARK dot peen marking machines offer unbeatable value for money, with affordable comprehensive pricing to help customers achieve faster ROI.

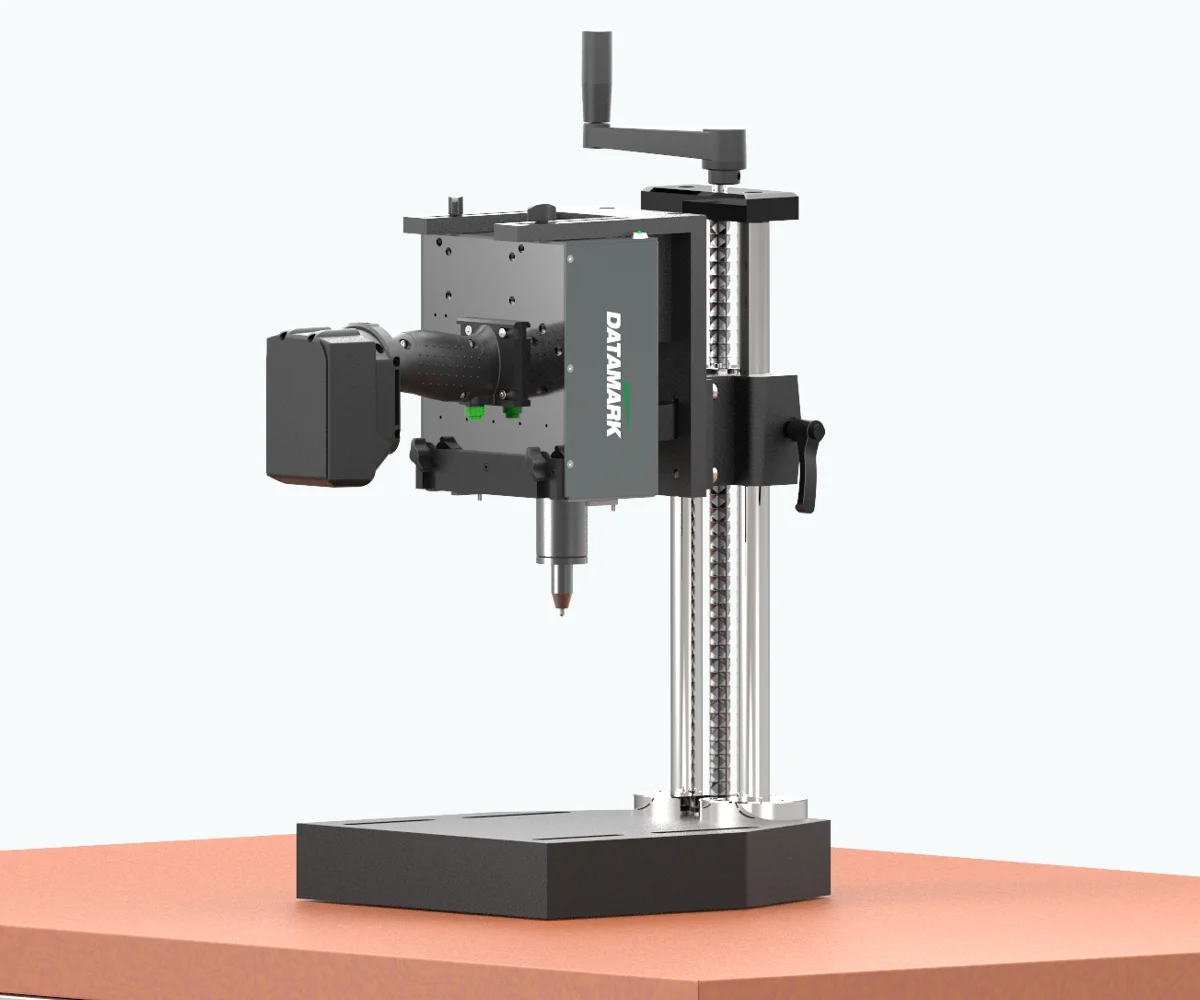

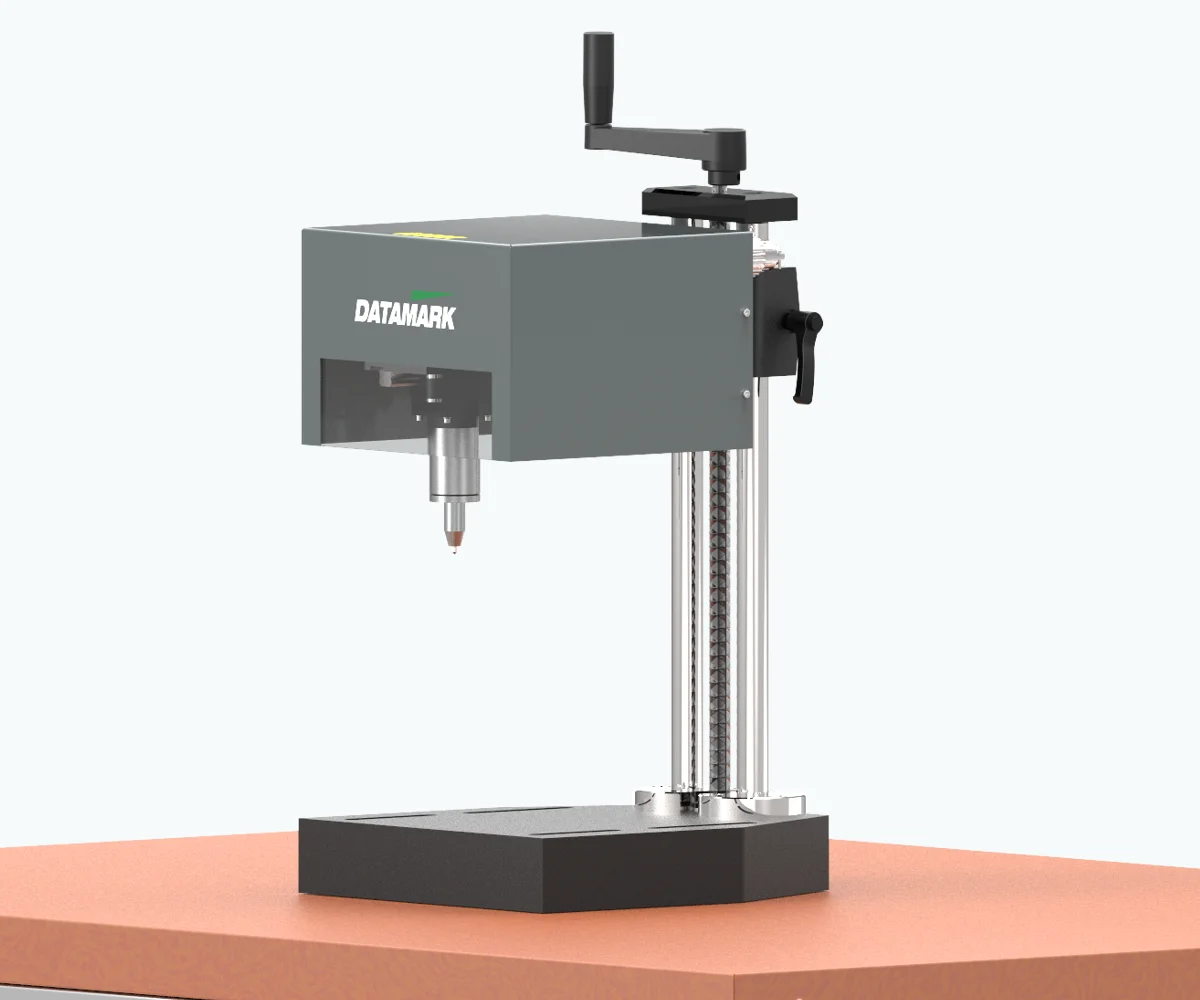

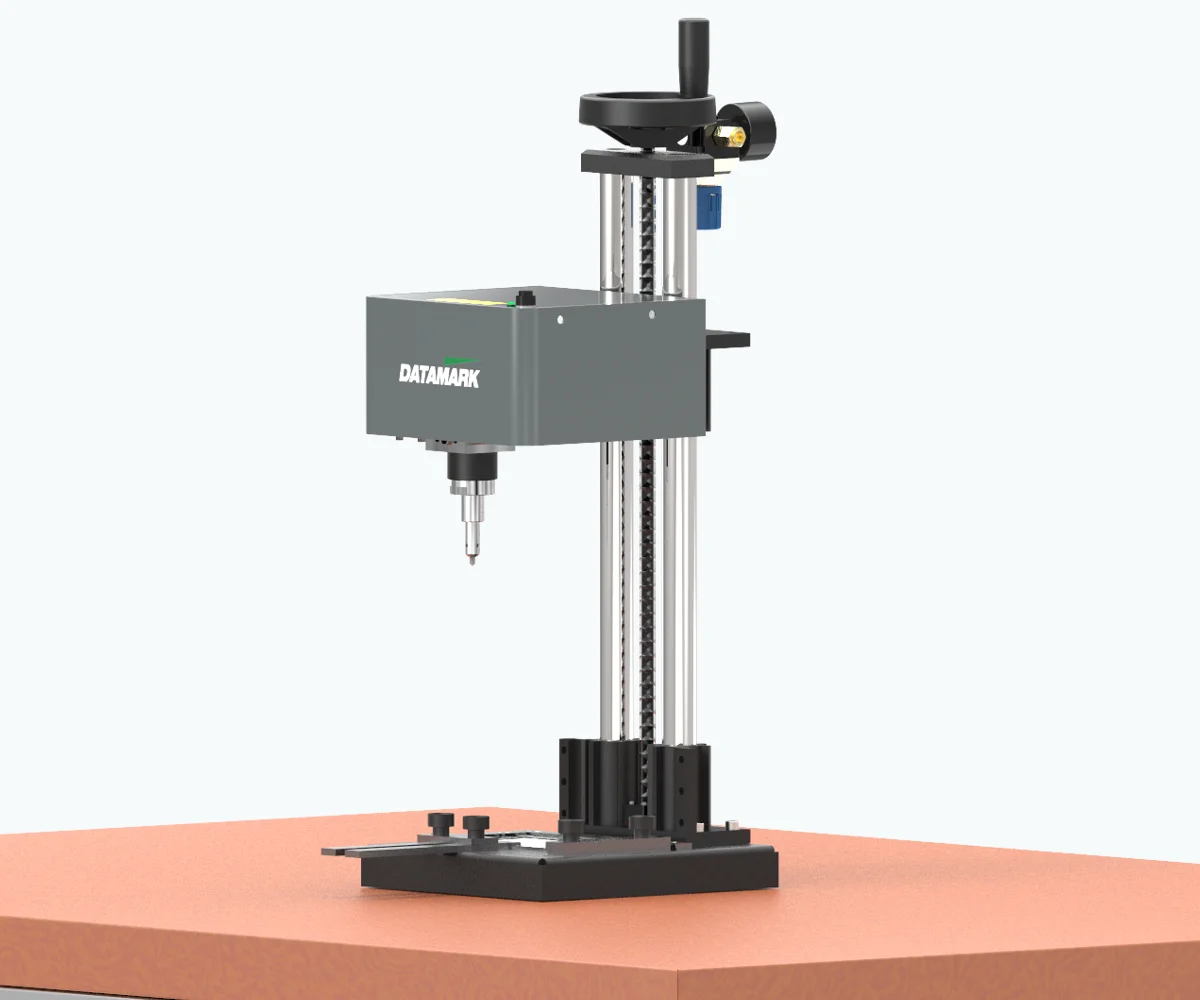

Datamark™ Dot Peen Marking Systems